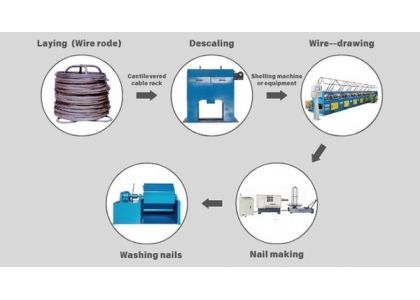

The nail making machine is mainly composed of four parts, among which the wire drawing part is the most important.

In the wire drawing stage, after purchasing the nail making machine, the first thing to do is to clarify the type of steel bars used for future nail making, such as new steel bars or scrap steel bars. Using scrap steel bars for wire drawing is relatively complicated, and the speed is not as fast as new steel bars, but the cost of scrap steel bars is low and the profit is very considerable. The use of finished wires for wire drawing has obvious speed advantages, can save some manpower, and the speed of nail production is also very fast.

Next is the nail making part. When the wire is drawn, the drawn wire will be fed into it through the fully automatic wire feeding head, so as to produce the adjusted semi-finished nails.

Then there is the polishing part. Put the finished semi-finished nails into the polishing machine, add sawdust, paraffin, gasoline and other chemical raw materials into the polishing machine, and through friction and impact, the shiny nails can be thrown out.

Finally, there is the packaging part. Although this part is less important than the first three steps, it is also very flexible, and users can order it according to their own needs.

For example, if your nails are mainly for export, you may need exquisite packaging to enhance the product image; if they are sold domestically and wholesaled in large quantities, you may pay more attention to the practicality and cost control of packaging.

In short, these four links of the nail making machine cooperate with each other to complete the production process of nails from raw materials to finished products. And it is easily to make other production like wire mesh, chicken cages, greenhouses, clothes hangers, car baskets, etc.