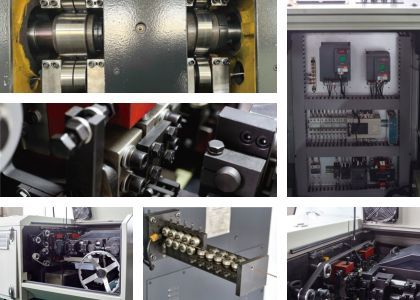

Some companies are constantly committed to the technical research and development and innovation of nail making machines, and have launched new fully automatic nail making machine equipment. The new fully automatic nail making machine is simple to operate, labor-saving, low-power and energy-saving, and has stable and reliable performance. After technological reform, it has become a powerful weapon for nail making. Its advantages of high benefit, high efficiency and high profit also make fully automatic nail making machines popular in the industry.

Some nail making machines adopt advanced automated production processes, from raw material feeding, cutting to molding in one go, which greatly improves production efficiency and ensures the high strength and corrosion resistance of nails. For example, through precise process control and high-quality material selection, nails are not easy to deform or break when subjected to huge pressure and tension; special surface treatment processes or the addition of corrosion-resistant alloy elements are used to keep nails in good use even in harsh environments.

Market demand and industry development:

With the development of industries such as construction and decoration, the demand for nails continues to grow, which also promotes the development of the nail making machine industry. Related research analyzes the scale, competition pattern and future development trend of the global and Chinese wire nail machine markets, providing a reference for the market development of the nail machine industry.

Nail machine manufacturers continue to expand the market, and their products are not only sold domestically, but also exported to many countries and regions overseas. For example, the high-speed nail making machines of us have been sold to more than 200 cities in China, and are exported to more than 40 countries including the United States, Germany, India, and Thailand.

Enterprise dynamics and cooperation:

Our nail machine companies will have some new dynamics in the production and operation process, such as expanding production scale and building new factories. For example, the relevant information of the annual production of 1,000 automatic computer program-controlled pneumatic nail guns, automatic nail making equipment and 10,000 tons of nail row projects, including construction location, environmental impact assessment, engineering nature, etc.

Enterprises may also cooperate to jointly carry out technology research and development, production and manufacturing or market expansion to enhance overall competitiveness.