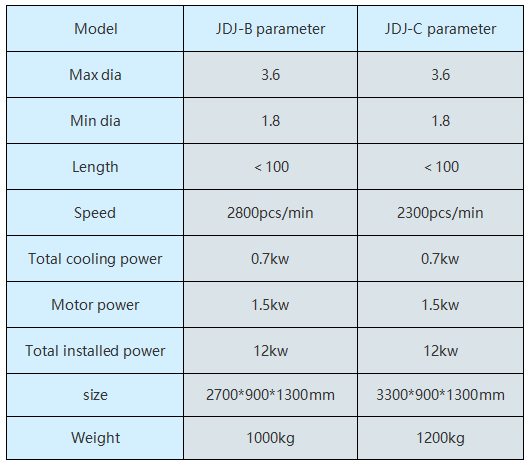

Max dia:3.6

Min dia:1.8

Length:<100

Speed:2800pcs/min / 2300pcs/min

Total cooling power:0.7kw

Motor power:1.5kw

Total installed power:12kw

Weight:1000kg / 1200kg

The coil nail making machine usually consists of multiple parts and has the characteristics of a high degree of automation. It adopts a vibrating feeding system for orderly conveying raw materials; its main motor adopts a speed-regulating motor, which is convenient for debugging and adjusting the productivity as needed to ensure the stable operation and precise processing of the equipment.

The automatic binding coil nail machine is equipped with an automatic binding device, which can realize multi-station synchronous operations such as rubber band sorting feeding, automatic material picking and stretching, automatic coil nail positioning, and automatic tying, reducing the labor of the operation and improving the level of factory automation.

The welding of the coil nail machine usually adopts an inverter DC welding power supply. This welding power supply has the advantages of stable welding current, fast welding speed, and high weld quality. The product will not have desoldering and cold welding, the welding points and welding angles are stable and accurate, the product is smooth to use, and the gun will not be stuck.

The automatic coil nail machine has the following advantages:

Reasonable design and simple structure

1.Good working stability: It adopts a reliable control system and components, which can maintain stable performance during long-term operation and reduce the probability of failure.

2.Easy to operate and use: It can realize automated production, and the operator only needs to perform simple settings and monitoring, which reduces the labor intensity.

3.Improve production efficiency: It can quickly make nails into coiled nails, greatly improving the production speed of coiled nails to meet market demand.

4.Ensure product quality: Process according to preset procedures and parameters to make the size, shape and quality of coiled nails more stable and consistent.

5.Strong adjustability: The automatic coiling machine can adjust the tension to improve the neatness of the roll. For example, some equipment can achieve the translation of the mounting seat and the reduction motor through components such as lead screws and drive motors, providing conditions for adjusting the tension of the row of nails.

6.Easy to achieve automatic connection: It can be used in conjunction with other related equipment (such as nail making machines, thread rolling machines, automatic packaging machines, etc.) to form an automated production line to further improve the degree of automation of production.

7.Have a certain degree of flexibility: It can be adjusted and switched according to coiled nails of different specifications and requirements to meet the production needs of various products.