With the continuous advancement of technology and the growing market demand, the company has entered a stage of rapid development. We actively introduce advanced production equipment and management concepts to expand production scale and improve production efficiency. At the same time, we increase investment in research and development and continue to launch innovative high-speed nail making machines to meet customers' needs for efficient production.

The equipment in our factory has significant advantages. The most advanced CNC machining center is adopted to ensure high-precision processing of parts, thus improving the overall performance and stability of the nail making machine. The automated production line not only greatly improves production efficiency, but also reduces human errors and ensures product consistency. Advanced testing equipment can conduct strict quality inspection on every production link to ensure that each nail making machine meets high quality standards.

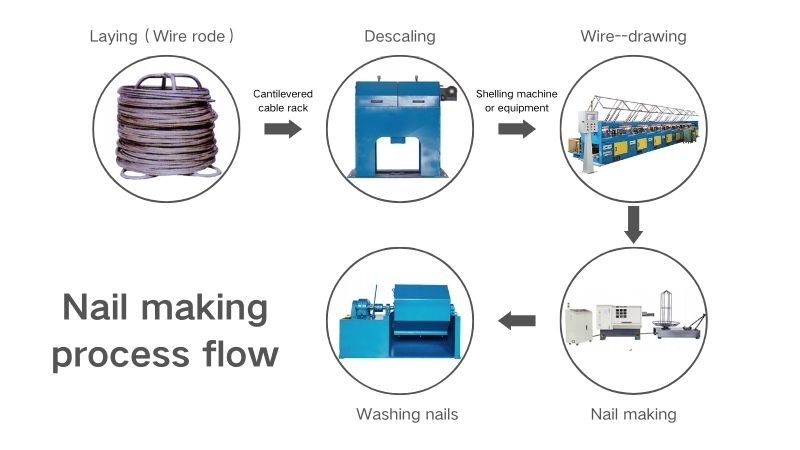

In terms of production process, we have strict and scientific management. First, develop a detailed production plan based on customer orders and market demand. Then, high-quality raw materials are selected and processed into various parts of the nail making machine through high-precision cutting, forging, turning and other processes. Then, in the assembly process, experienced technical workers strictly follow the process requirements to assemble and conduct preliminary debugging. Afterwards, the assembled nail making machine undergoes comprehensive performance testing and quality inspection to ensure that its various indicators meet the design requirements.Finally, qualified products are carefully packaged and ready for shipment.

Today, we have a high-quality, professional R&D team, as well as advanced production equipment and a strict quality control system. The company's product line is rich and diverse, covering nail making machines and high-speed nail making machines of various models and specifications, which can meet the diverse needs of different customers.

Advanced technology: For example, the latest CNC technology, automated control system, intelligent monitoring system, etc. are adopted to achieve high-precision and high-efficiency production.

High efficiency: The equipment has the characteristics of high production speed and low energy consumption, and can produce more products per unit time while reducing production costs.

High precision: Able to produce products with extremely high dimensional accuracy and minimal errors, ensuring the stability and consistency of product quality.

Versatility: One piece of equipment can complete a variety of processing procedures or be able to adapt to the production of a variety of products of different specifications, improving equipment utilization and production flexibility.

Reliability: The equipment operates stably and has a low failure rate, reducing production interruptions and maintenance costs caused by equipment failure.

Degree of automation: Highly automated equipment can reduce manual intervention, reduce labor costs, improve production efficiency, and reduce human errors.

Environmental protection and energy saving: It complies with environmental protection standards and has an energy-saving design to reduce the impact on the environment and reduce energy consumption.

Easy to maintain and operate: The equipment has a reasonable structure and is easy to maintain and maintain. The operation interface is simple and intuitive, making it easy for workers to quickly master operating skills.

Customization capabilities: The equipment has certain customization functions and can be adjusted and improved according to the special needs of customers.