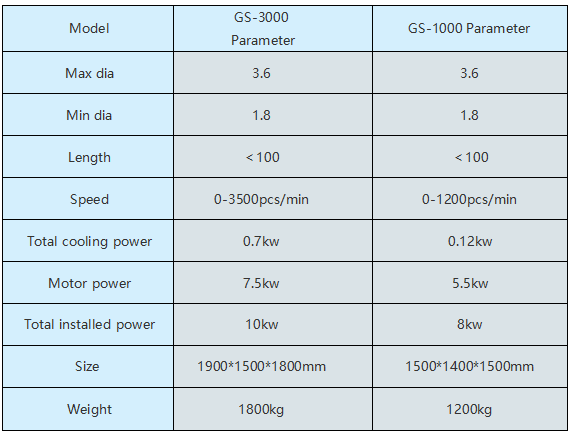

Max dia:3.6

Min dia:1.8

Length:<100

Speed:0-3500pcs/min / 0-1200pcs/min

Total cooling power:0.7kw / 0.12kw

Weight:1800kg / 1200kg

Thread rolling is a cold working method that forms threads by causing plastic deformation of metal. It can roll external threads of various diameters and has obvious advantages. It has high production efficiency, fine surface roughness of the formed threads, high thread strength and surface hardness, and can fully guarantee the mechanical properties of parts. It is a widely used thread processing method in the fastener and machinery industry.

Based on the advantages of similar products at home and abroad, our company's high-speed thread rolling machine has been comprehensively improved and improved many times, and is at the leading level among similar products. It is mainly used for the processing of new special-shaped nail products such as threaded nails and ring nails.

This machine has many characteristics. It adopts an electromagnetic vibration feeding system and is equipped with automatic control feeding facilities to achieve accurate feeding; the synchronous feeding mechanism can ensure the stability of feeding; the main motor is a speed-regulating motor, which is convenient for debugging and can flexibly adjust the productivity according to needs. In addition, its working environment is clean, and the special-shaped nails produced are clean and shiny.

This machine has a reasonable structure, convenient operation and reliable action. It is an ideal and efficient production equipment that can be used for processing straight rod threads of various diameters and lengths as well as various special-shaped nails.

Its basic structure consists of four parts: vibrating feeding system, thread rolling forming system, main transmission system, and electrical control system. Each system works together to achieve efficient and accurate thread processing.