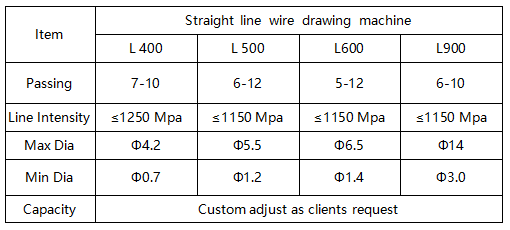

Passing:7-10 / 6-12 / 5-12 / 6-10

Max Dia:Φ4.2 / Φ5.5 / Φ6.5 / Φ14

Min Dia:Φ0.7 / Φ1.2 / Φ1.4 / Φ3.0

Capacity:Custom adjust as clients request

In the nail making process, wire drawing is the key first step. The mechanical equipment of nail making machine includes nail making server, wire drawing machine, straightening machine and grinding and polishing machine, among which wire drawing machine plays an important role in wire drawing.

The purpose of wire drawing is to process the raw wire into the required diameter of the nail, and to ensure that the raw wire is smooth, uniform in diameter, and not bent, and at the same time, the physical strength and properties of the raw material cannot be destroyed.The wire drawing machine is an important equipment for metal wire processing. It consists of wire laying, wire drawing, water cooling, wire taking up and wire arrangement. The electrical transmission part mainly relies on the wire laying motor, wire taking up motor and wire arrangement motor. Its production quality and efficiency are extremely important to the enterprise.

There are many ways to classify wire drawing machines. From the product terminal, it can be divided into large drawing machines, medium drawing machines, small drawing machines and micro drawing machines; from the internal control method and structure, there are water tank type, pulley type, straight-in type, etc. For products with different requirements, precision, specifications and different types of metals, wire drawing machines of corresponding appropriate specifications can be selected.

This set of wire drawing equipment has a wide range of uses and is an ideal choice for drawing low-carbon steel. It is often used for drawing iron wire, steel wire, steel cable, building components, galvanized steel wire, metal mesh, nail making and other wire drawing work.Its structure consists of a main reducer, a mold box, a guide wheel frame, a wire drawing frame and an electrical control system. Each wire drawing reel is driven by a motor through a gear coupling to rotate the first gear reduction, thereby driving the reel to rotate.In short, choosing a suitable wire drawing machine and operating it correctly is the key to doing a good job of wire drawing nail raw materials.

As an important equipment for nail wire processing, this product wire drawing machine has many significant advantages.

1. the wire drawing machine can achieve high-precision wire drawing operations. It can accurately draw the metal raw wire to the required diameter, and ensure that the diameter is uniform and the error is extremely small, so as to meet various application scenarios with high requirements for nail precision.

2. the wire drawing machine has efficient production capacity. It has a high degree of automation and can continuously and stably carry out wire drawing work, which greatly improves production efficiency and can complete the processing of a large number of raw wires in a short time.

3. the wire drawing machine has strong adaptability. It can handle many different types of metal materials, such as iron wire, steel wire, steel cable, etc., whether it is low-carbon steel or other alloy materials, it can easily cope with it.

4. the wire drawing machine can also retain the physical strength and properties of the raw materials to the greatest extent while ensuring product quality. Through a reasonable drawing process, the performance of the metal material will not be degraded due to the processing process.

5. the operation and maintenance of the wire drawing machine are relatively simple. After simple training, the operator can master its operation method proficiently, and the daily maintenance of the equipment is not complicated, which reduces the manpower cost and maintenance cost of the enterprise.

6. Our wire drawing machine has high stability and reliability. During the long-term operation process, it can maintain a stable working state, reduce failures and downtime, and provide a strong guarantee for the continuous production of the enterprise with low price and cost.

Our wire drawing machine plays an irreplaceable and important role in the processing of nail raw wire with its advantages of high precision, high efficiency, strong adaptability, performance guarantee, easy operation and high stability.