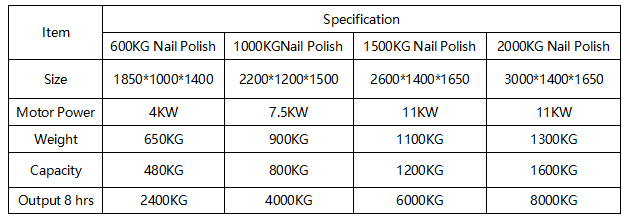

Size:1850*1000*1400/2200*1200*1500/2600*1400*1650/3000*1400*1650

Motor Power:4KW/7.5KW/11KW/11KW

Weight:650KG/900KG/1100KG/1300KG

Capacity:480KG/800KG/1200KG/1600KG

Output 8 hrs:2400KG/4000KG/6000KG/8000KG

The nail making machine consists of mechanical equipment such as nail making server, wire drawing machine, straightening machine and grinding and polishing machine. Grinding and polishing are crucial to making smooth nails.

Putting raw materials such as paraffin wax and sawdust into the grinding and polishing machine can round off the excess filaments or edges on the semi-finished nails, thereby making nails with smooth surfaces. This process not only makes the nails smooth, but also removes oil and rust spots on the surface. At the same time, a wax layer is formed on the surface of the nails to protect the nails from rusting, which is conducive to subsequent processing and can also improve the appearance of the product, thereby improving its quality and sales price.

Our nail polishing machine has the following advantages:

1. Improve the quality of nails: It can polish the semi-finished nails to be smooth and round, remove the oil, rust spots and excess filaments and edges on the surface, and form a wax layer to protect it, which greatly improves the appearance quality and rust resistance of the nails, thereby improving their quality.

2. Efficient processing: It has a large capacity and high processing capacity, and can process a large number of nails in a short time to meet the needs of large-scale production.

3. Easy to operate: The design is humanized, the operation process is simple and easy to understand, and the operator can get started after simple training, which reduces the cost of human training and the possibility of operating errors.

4. Save manpower and time: The degree of automation is relatively high, which can effec

tively reduce the time and labor intensity of manual operation and improve production efficiency.

5. Flexible customization: The detachable and turnover nail barrel can be customized according to the actual needs of the factory, which is convenient for the transportation and storage of nails in the factory and improves the flexibility of the production process.

6. Improve work efficiency: Used in conjunction with equipment such as magnetic lifts, it can further optimize the work process, reduce work intensity, and greatly improve overall work efficiency.

7. High cost-effectiveness: By improving the quality and production efficiency of nails, the added value and market competitiveness of products can be increased, bringing better economic benefits to the enterprise.

Our nail polish making machine price concessions, by using the grinding and polishing machine rationally and giving full play to its advantages, you can produce smooth and high-quality nails and enhance the market competitiveness of your products.